This post may contain affiliate links, which means we may receive a commission, at no extra cost to you, if you make a purchase through a link. Please see our full disclosure for further information.

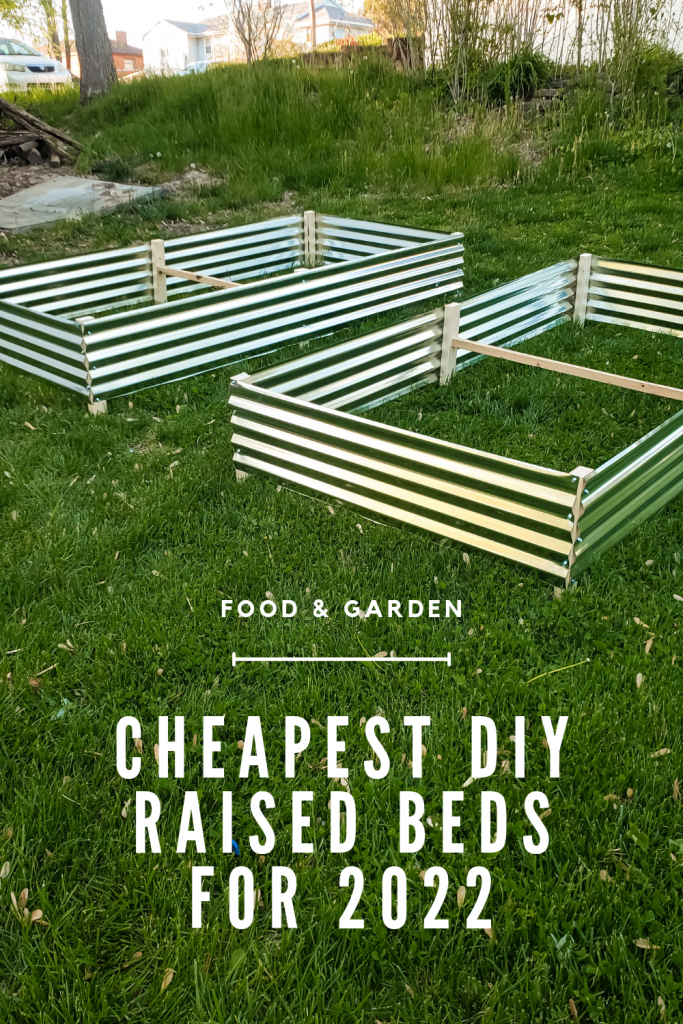

It has been a long-time dream of mine to one day have a garden and be able to grow some of my own food. Since moving to the milder climate in Kentucky, it really began to seem feasible. However, we bough a property in town which has a sloped gradient on one side and then a mild incline up the far side, creating a bowl for rain water to accumulate in. Between the standing water and the clay composition of our soil, we realized our best option would be to make a DIY raised bed rather than tilling and planting directly in the ground.

But here we are in 2021 with gas prices rising and taking the cost of many products with it – most importantly lumber and building supplies. Our budget for home renovations is quickly shrinking, so we needed to figure out the most cost effective way to begin raised bed gardening. We scoured the internet for the best information on how to build raised beds, and we ended up using some insight from MK Library, even though we were far from following his plan.

Planning a DIY raised bed

Our first choice would have been wood. But for two 4ft by 8ft beds, we were looking somewhere around $150. The next option we considered was cinder block. Our local Home Depot was out of the usual 8x8x16 blocks when we first looked, but they got some in later at $1.50 each. This method of building beds would have cost us around $120 for two beds. A friend suggested used railroad ties, which I have now heard is bad for growing vegetables in, but they were in the $16-$20 range each, and that was even more expensive than most options. After more research we priced out galvanized corrugated steel siding, and found that we could make two 4×8 beds for $70. Jackpot!

Materials

Here’s a breakdown of what we bought, where we found it, and how much it cost us. While building material prices will differ across the country and as time passes, we are fairly confident that this is hands down the most cost effective way to build raised beds.

- 3 sheets of corrugated galvanized steel 2’x8′ ($18 each at Lowes – Home Depot was out but theirs were only $12.80 or something!)

- 2 2″x3″x8′ ($5 at Home Depot)

- 1 2″x2″x8′ (already had ours but they’re under $3)

- Metal to metal self drilling screws ($6)

- Wood screws (already had some)

Tools

How to build a cheap raised bed

They say to measure twice and cut once, so that’s where I began. I measured and cut our 3 sheets of steel in half long ways first. Then I took one of the three sheets, now cut in half, and cut it in half short ways. At this point we had four 1×8 foot pieces of siding, and four 1×4 foot pieces for the ends of the beds. I wore gloves so I wouldn’t cut myself on sharp edges and took a pair of tin snips to the sheets, and they cut fairly easily. Be warned – the cut edges of corrugated steel are VERY sharp.

Next I took our Dewalt Skill Saw and cut our two 2x3s into 16 inch segments. I cut them this way so that we can use the excess 4″ of each to “anchor” the bed into the ground by being buried a little below ground level. You could also just cut 12″ segments if you don’t want to do this, and just “set” the beds on level ground.

Using self drilling metal to metal screws (Home Depot $6) I attached a 2×3 to each end of an 8 foot piece of sheet metal. Making sure they were on what would become the inside of my raised bed. I attached 8 corner posts in this fashion.

Next, I propped these pieces up and one at a time I lined up the end pieces, and screwed these onto the corner wood posts the same way. Once all eight corners were done, both beds were able to stand unsupported. (Edit: the following is what I added as an unnecessary but helpful component – as it turns out the following instructions are quite necessary in order to prevent the middle of your beds from bowing outwards with the weight of added soil. So, read on!)

Additional tips for your DIY raised bed

Part of the cost effectiveness of this plan is that very little wood is used and there is no wooden frame. However, this decreases the structural stability of the beds and can allow for bowing of the metal over time as the soil in the beds settles and holds water. So my husband came up with a great solution for stabilizing the beds a little more.

Cutting the wood to 16″ pieces meant there was enough for 6 legs per bed, and we had only used 4 for the corners. Knowing that the beds were 4′ across and I’d be using two 2×3″ posts, I cut a piece of scrap 2×2 we had in the garage to 3’8″ and used wood screws to attach it to the center of the two remaining 2x3s. Then I used more wood to metal screws to attach this little frame to the center of the length of the bed. This way there’s something “pulling” the sides of the galvanized corrugated steel sheets inwards and negating the bowing that could have happened, effectively stabilizing the beds without a real frame. It looked good and seemed effective, so we repeated the process for the second bed.

And that was it. We have two 4×8 raised beds ready for soil and planting. Before we fill them with soil we are going to dig into the graded hillside a little so the beds sit close to level without being at the bottom of our little valley. We will hopefully have soil delivered later this week and be able to start transplanting our tomatoes and other vegetables into the beds we just made.

So this is how we built two 4x8ft raised garden beds the cheapest possible way. We’ll keep you updated on how well they hold up! But for now, wish us happy gardening and a green thumb!